Machine Tending: Designing trays and drawer systems for machine tending robot cells

Machine tending is by far the most common collaborative robot application. Despite their widespread use, each application must still be somewhat customized to unlock the full potential value. How much autonomy is sought? Can machine-to-tray cycle be optimized? How should the tray be configured?

This article is intended to guide cobot users through one of the main design considerations for their machine-tending robot cell: whether you should choose configurable trays, or a drawer system.

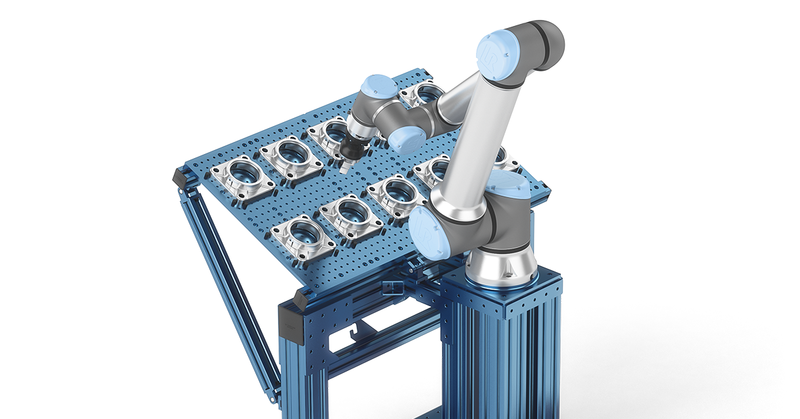

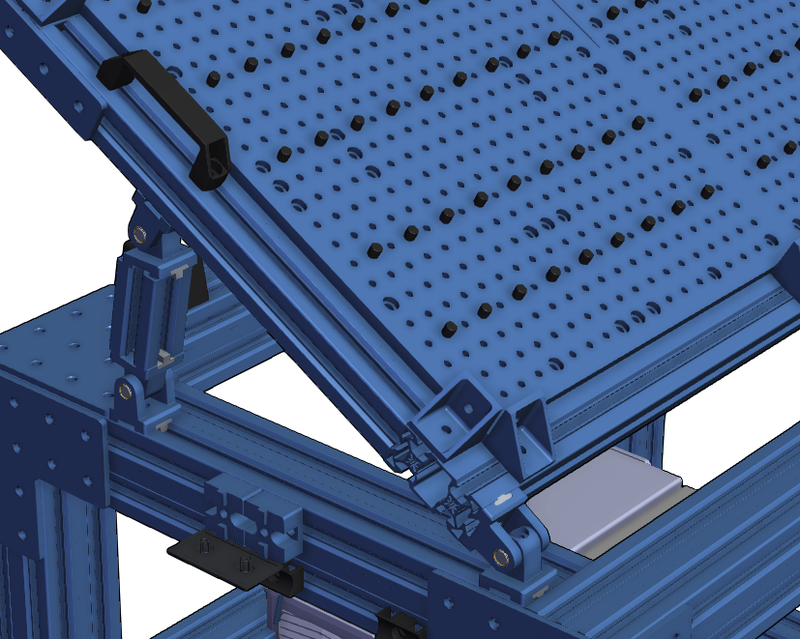

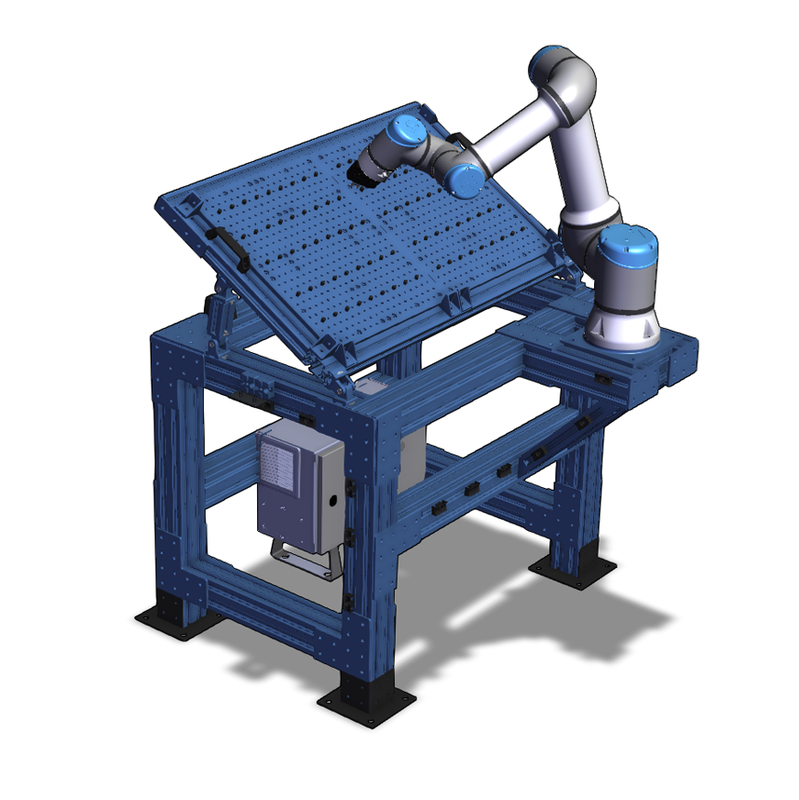

Configurable trays

Trays are typically less expensive and simpler to deploy and program than drawers, but they offer less autonomy in terms of part-holding capacity.

Configurable trays consist of a base plate on which are attached the threaded nylon pins, which acts as a datum locator. Using these nylon pins, the work surface of the base plate can be configured to create repeatable locators specific to the part being tended. Part density on the base plate is easily adjusted using configurable pins.

Depending on the part dimensions, we often see users loading anywhere from 16 to 32 parts per base plate. Some users also prefer to have easily removable base plates, which enables off-line restocking of the trays. Last but not least, cycle time can be improved by adjusting the angle of the tray facing the robot.

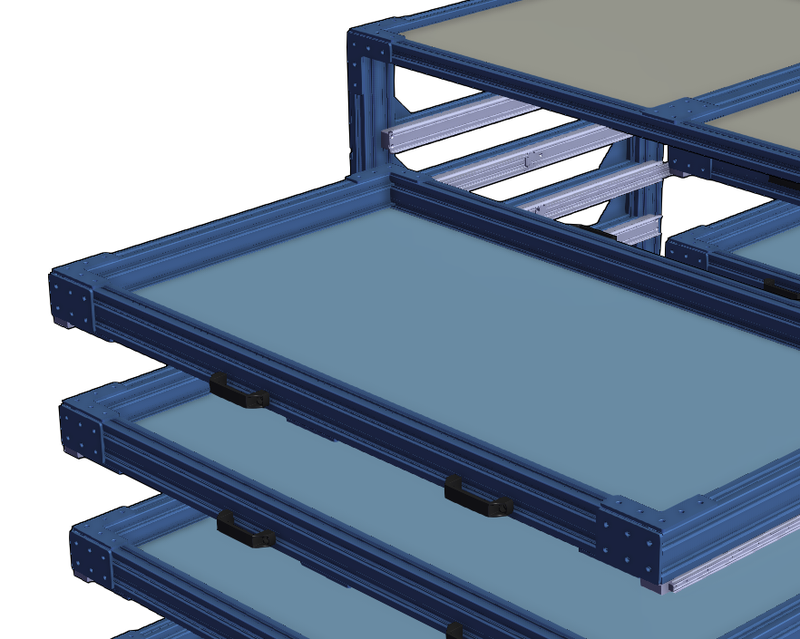

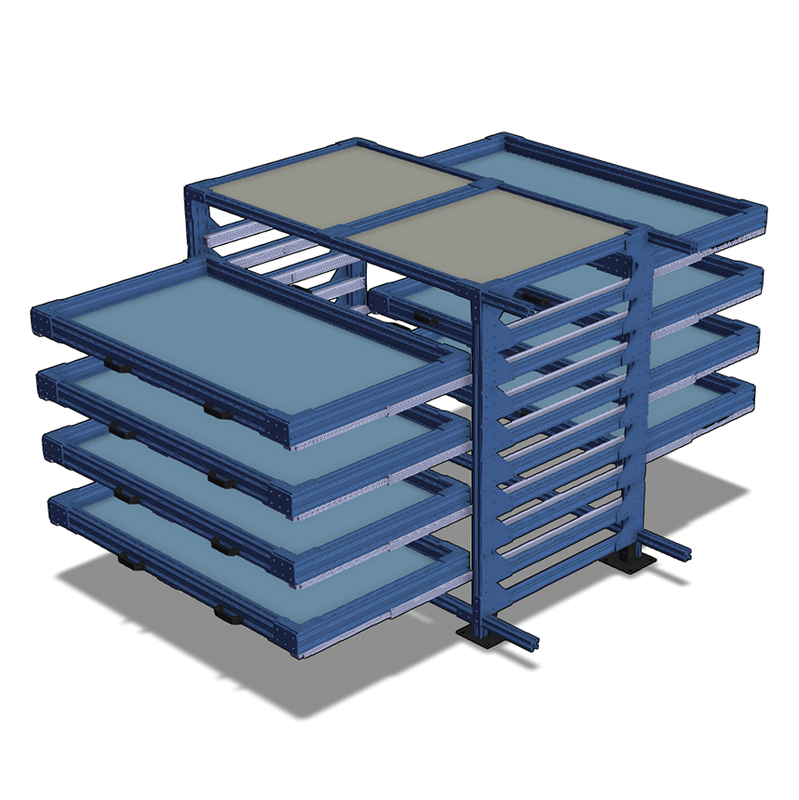

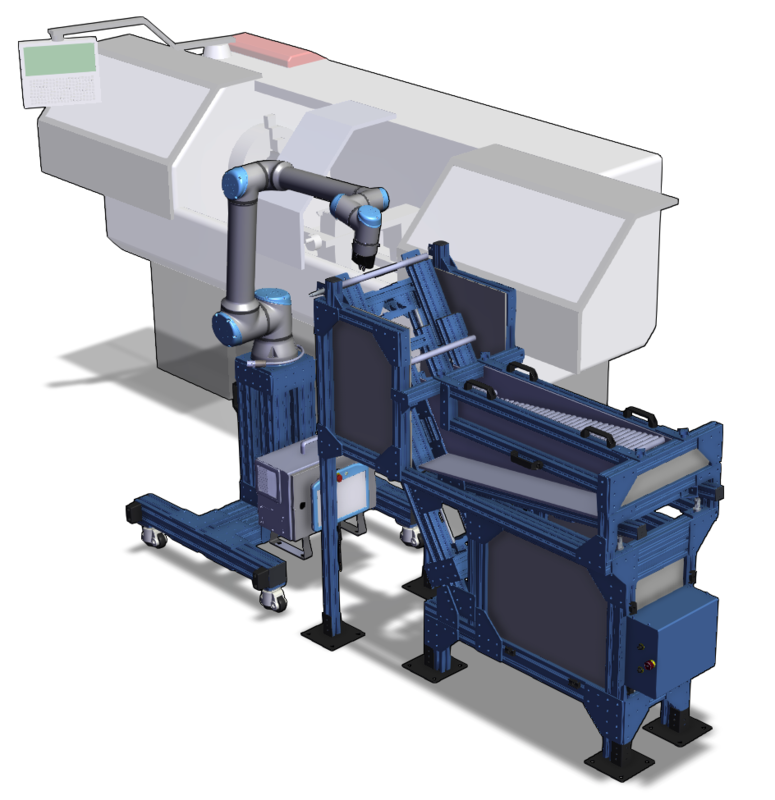

Drawer systems

Drawer systems typically involve 3 to 5 drawers stacked on top of each other, each holding 32 to 50 parts. Drawer systems thus have a higher part-holding capacity than trays—often ranging from 160 to 250 parts total—and they can operate autonomously for 8+ hours. However, they are generally more expensive and require greater setup expertise than configurable trays.

Drawer systems can be “manual” or automated. With manual drawer systems, the robot arm simply pulls the drawers in and out to open and close them. Automated drawer systems, by contrast, are opened and closed with electrical actuators that work in tandem with the machine and cobot.

Trays vs. drawers

The table below compares the main characteristics of configurable trays and drawer systems for machine tending.

| Drawer System | Configurable Trays | |

|---|---|---|

|

|

|

| Parts Capacity | 160 - 250 parts | 16 - 32 parts |

| Configuration | Up to 5 drawers | Up to 2 trays side-by-side |

| Part Dimensions | Up to 150mm x 150 mm 150 mm | Up to 150mm x 150 mm 150 mm |

| Autonomy Gain (at 2 min/part cycle) | Up to 8 hours | 30 min to 1 hour |

Whether you choose configurable trays or a drawer system, your manufacturing process stands to gain improved productivity and autonomy.

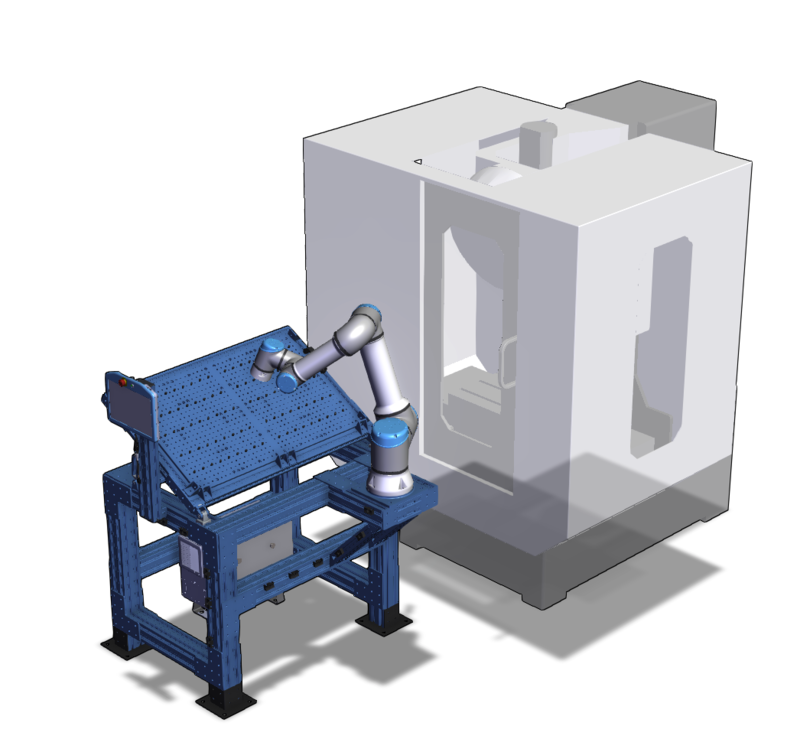

Machine Tending Feeder for UR16e

Automated Rod Feeder with Heavy-Duty Robot Stand for UR10e/16e

Ready to get started? Explore machine-tending robot cell designs by searching for “machine tending” in our public design library. Alternatively, open a live chat session anytime to talk with an application engineer about your specific machine-tending needs.