ROBOTIC MACHINE TENDING

Automate CNC machine operations

Vention’s Robotic Machine Tending solutions remove manual and repetitive tasks from your CNC operations by automating the loading and unloading process of your CNC. We offer various options from a complete or self-deployed solution, to hardware and automation kits. Compatible with a range of accessories, our solutions can provide machine autonomy without interruptions.

WHAT DOES ROBOTIC MACHINE TENDING SOLVE?

Automating lathe, injection mold, & CNC machining

Quick payback

See ROI from your machine operator robot in six months or less allowing you to accelerate your automation roadmap.

Easy to assemble

Assemble your full robotic machine tending solution in as little as four to eight hours.

Fast lead time

Receive your CNC robot in two weeks or less to start automating faster.

Robot-agnostic

Use with your preferred CNC robot brand of FANUC, Universal Robots, and Doosan.

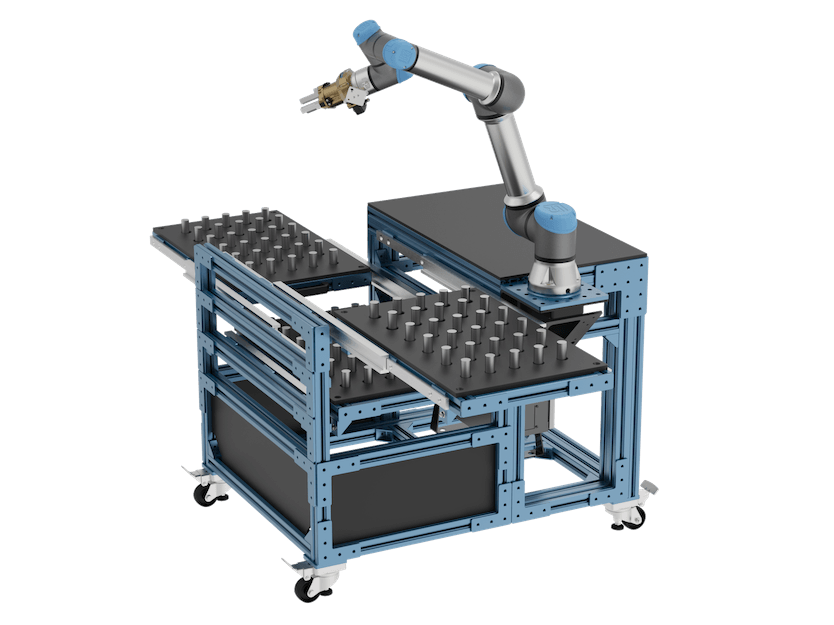

COBOT MACHINE TENDING CONFIGURATIONS

Configure your CNC machine robot cell

Drawer system

Best for:

Large volume production where long machine autonomy is required.

Tray system

Best for:

High mix production environment that requires quick changeovers. Trays can be easily reconfigured to part geometry using positioning pins.

Range extender & Part presenter

Best for:

Increased horizontal reach and ideal when one robot arm tends to multiple CNC machines.

Overhead & Part presenter

Best for:

Optimized footprint, increased reach, tend to multiple CNC machines.

TEMPLATES

Select a machine tending robot template to get started

Find fully customizable templates by inputting your specifications.

CALCULATE ROI

Earn strong ROI with Vention Robotic Machine Tending

Your process

Your design

Your savings

Educational Resources

Robotic machine tending resources to get you up and running

Explore our technical documents, video tutorials, and deployment guides for in-depth information about Vention products and tools.

Request a Quote

Expect a call within 24 hours. Yes, we're quick.