Bringing automotive inspection jigs into the digital manufacturing era

Until today, inspection and dimensional jigs for CMM and 3D scanners have been custom-engineered projects, taking several months to design and manufacture. Working with our clients, we often hear that a jig for a car floor panel, hood, or door regularly takes up to 16 weeks lead-time from design to delivery. This is mostly caused by the traditional design-to-build workflow, where mechanical designers search for vendor parts online, import the 3D model of those parts in their desktop-based CAD software, create 2D drawings, get quotes from various fabrication workshops, and eventually, launch the fabrication process. The complete separation between the vendor component selection, design, and fabrication steps adds several non-value-added “interface tasks” fueling this lead time. For example, creating 2D drawings is still required today for the sole purpose of supporting the fabrication steps.

In today’s short product lifecycle environment, this 16-week lead time can represent up to 10% of the car’s life. Needless to say, improving this lead time would not only significantly improve the ability of metrology departments to ramp up the production of new car models, but also improve the business case for the entire car.

Interestingly, as part of our ongoing work with large automotive manufacturers and metrology equipment OEMs, we were able to accumulate a fact-based perspective on lead time and cost to complete inspection jig projects for various car components in the context of a digital manufacturing environment.

Lead time

On lead time, Vention users can navigate the design and build process in as fast as 3 days, as opposed to the 16 weeks (i.e. 112 days) mentioned above. That said, on average, users navigate the design process in 10-15 days and complete the shipping and assembly steps in another 10-15 days. This total lead-time of roughly 25 days represents a 4.5X improvement over the traditional workflow.

Cost

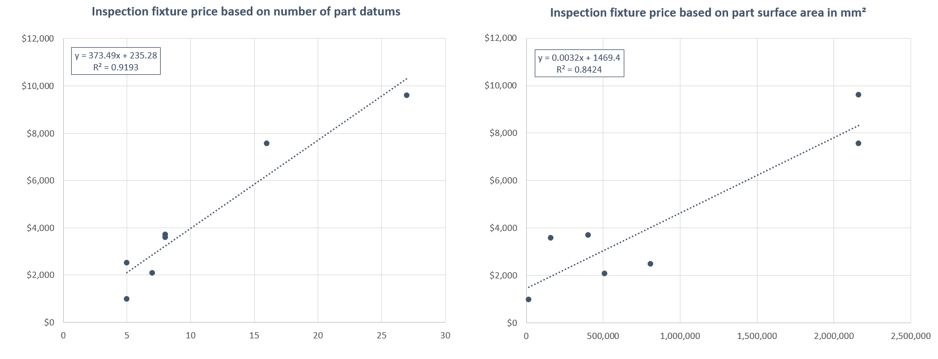

On cost, the statistical review of inspection jig designs created on Vention revealed that part datum and part surface areas are the primary drivers, behaving as per the following linear regression:

- Jig cost = $0.00125/mm x Part surface (mm²) + $255 x Part datum count + $450 (base cost)

For example, a car hood measuring 1250mm x 1000mm and having 8 datum across the part would cost approximately $4,000:

- $3990 = $0.00125 x (1250mm x 1000mm) + $255 x 8 + $450

The cost measured above appears to be approximately 40% less than for an inspection jig design and manufactured using a traditional approach.

Even though not all types of inspection jigs can currently be designed and manufactured on a digital platform like Vention, this clearly demonstrates that value creation potential truly exists for the end-users. It’s now a matter of time before an increasingly wide range of inspection jig applications are supported.

Inspection Jig for Hood