ROBOT 7TH AXIS

Extend the range of your robot arm

Vention's Robot 7th Axis uses a robot transfer unit or gantry system as robot actuator (robot range extender), and is plug & play and pinch-point-free. With more actuator types and lengths to choose from, the 7th axis is the most versatile and powerful robot actuator line on the market. Each 7th axis configuration is robot-agnostic, making it fully compatible with FANUC, Universal Robots, Doosan, and others.

WHAT DOES A ROBOT 7TH AXIS SOLVE?

Linear robot range extender for increased efficiency

Easy to program

Program and deploy your robot actuator entirely code-free with an intuitive user interface.

Quick to assemble

Assemble your robot 7th axis quickly, with simple instructions and a 3D model of your design.

Fast delivery

Receive your order in as little as one to three days to start automating faster.

Robot-agnostic

Use with your preferred robot brand of FANUC, Universal Robots, Doosan, & others.

ROBOT 7TH AXIS CONFIGURATIONS

Configure your solution

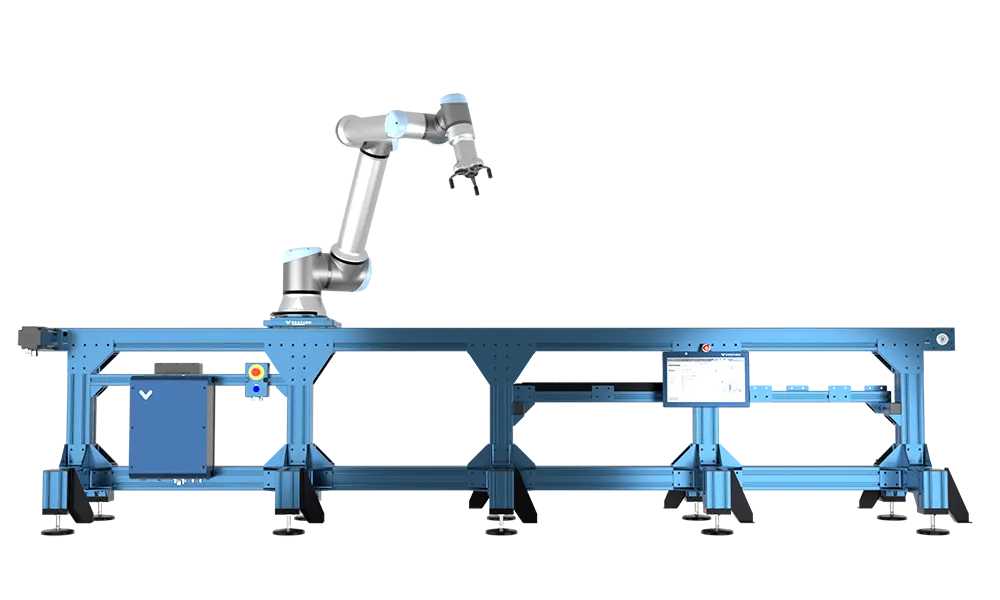

Floor-mounted 7th axis

Best for:

Increase the reach of your small to medium payload cobot with a range extender. This configuration is compatible with all of Vention's linear actuators.

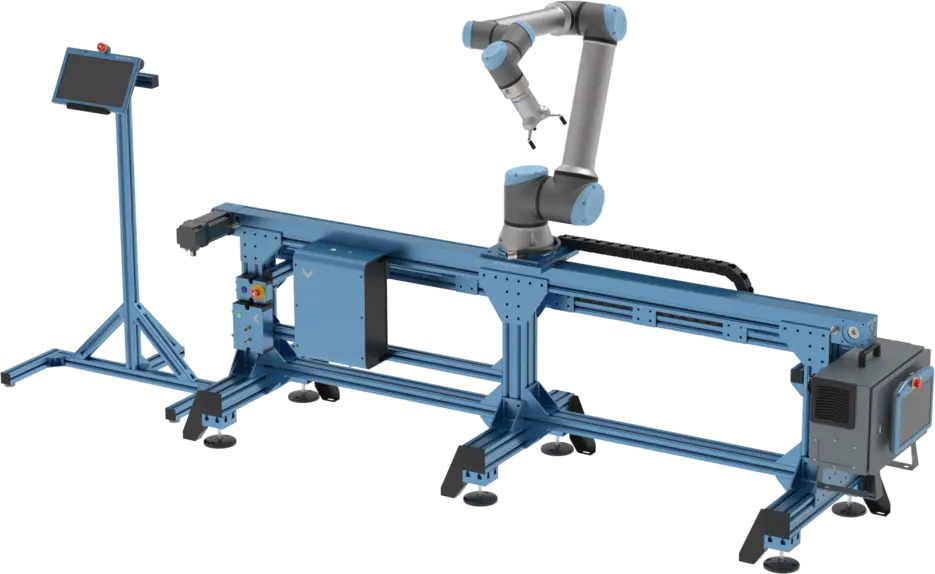

Overhead 7th axis

Best for:

Increase the reach of your small to medium payload cobot in limited spaces with a floor- or ceiling-mounted overhead range extender. This configuration is compatible with all of Vention's linear actuators.

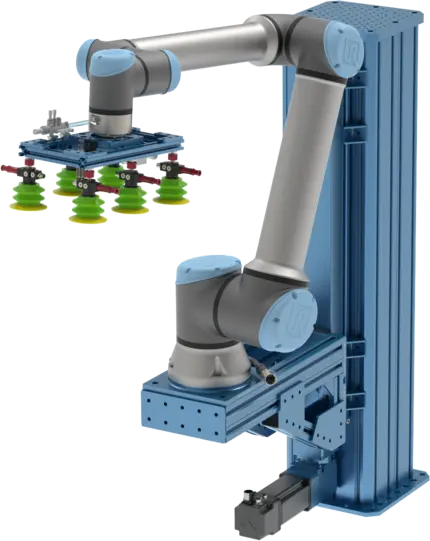

Telescopic 7th axis

Best for:

Increase the reach of your heavy payload cobot with a range extender using Vention’s XL extrusions and our heavy-duty linear guides.

Custom vertical 7th axis

Best for:

Increase the reach of your heavy payload cobot in limited spaces with a floor- or ceiling-mounted overhead range extender using Vention’s XL extrusions and our heavy-duty linear guides.

TEMPLATES

Select a template to get started

Find fully customizable templates by inputting your specifications.

CUSTOMER STORY

Increasing productivity via an overhead robotic 7th axis

Challenge

To meet the demands of an important production contract, which required regrouping three CNC lathes and automating the entire machine-tending and post-machining inspection system with a single UR10 robot.

Solution

A 40-foot overhead 7th-axis range extender, with fully configurable linear speed and acceleration. The 7th-axis was deployed in 3 weeks (vs 3 months) and with 5x times the cost savings compared to a traditional approach. The end-to-end solution brought a 100% increase in productivity, moving from 300 parts to 600.

Vention Products

Educational Resources

Robot 7th axis resources to get you up and running

Explore our technical documents, video tutorials, and deployment guides for in-depth information about Vention products and tools.

Request a Quote

Expect a call within 24 hours. Yes, we're quick.