The imperative for faster machine design

Today’s engineering managers are under significant pressure to design products that can evolve as fast as the needs of the customers they aim to serve. As a result, we see car platforms with a shelf-life of three years instead of five years become the norm, and we see electronic products adopt an obsolescence schedule of one to two years instead of three years. This new reality is significantly disrupting how end products and supporting production equipment (i.e., machines) are being designed and manufactured.

At its highest level, a shorter product lifecycle means that the window to depreciate related production equipment is also shorter, creating a need for production assets that can be readily designed, deployed, and repurposed at a low cost. Despite such pressure, custom industrial equipment is still being designed and manufactured like it was 20 years ago, relying on custom-manufactured parts and welded structure assemblies. Those techniques are both time-intensive and costly. Modular hardware platforms, such as T-slot aluminum extrusions, could be a strong solution to faster machine design and build, but adoption to date has remained limited. It’s time to reconsider this decision.

Limitation of existing T-slot aluminum extrusion systems

An industrial hardware platform can be described as a coherent library of parts where compatibility is certified. For such a platform to enable end-to-end machine design while providing a significant gain in cycle time and cost, it must include structural, motion, and control components.

T-slot aluminum extrusions and associated assembly plates are often the foundation of such hardware platforms. In principle, such extrusions could be used for various applications, ranging from test rigs to assembly jigs to machine frames. That said, much of industrial equipment still relies on welded structure assemblies, which have a long lead-time and are costly to design and manufacture due to the workmanship involved.

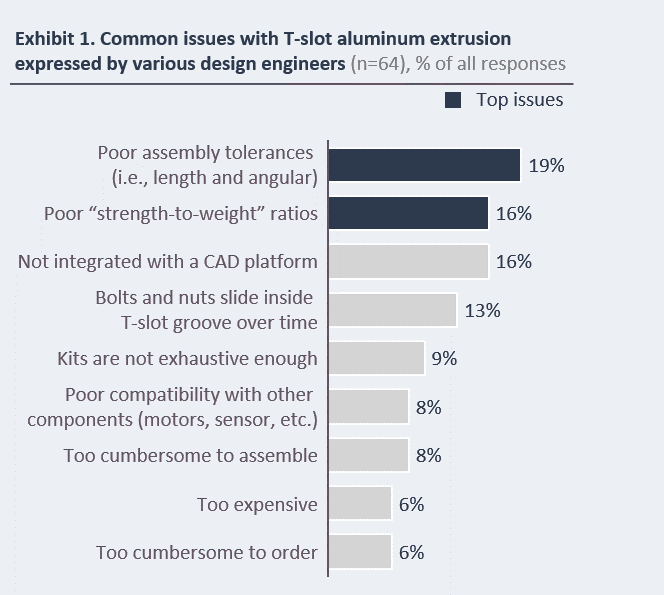

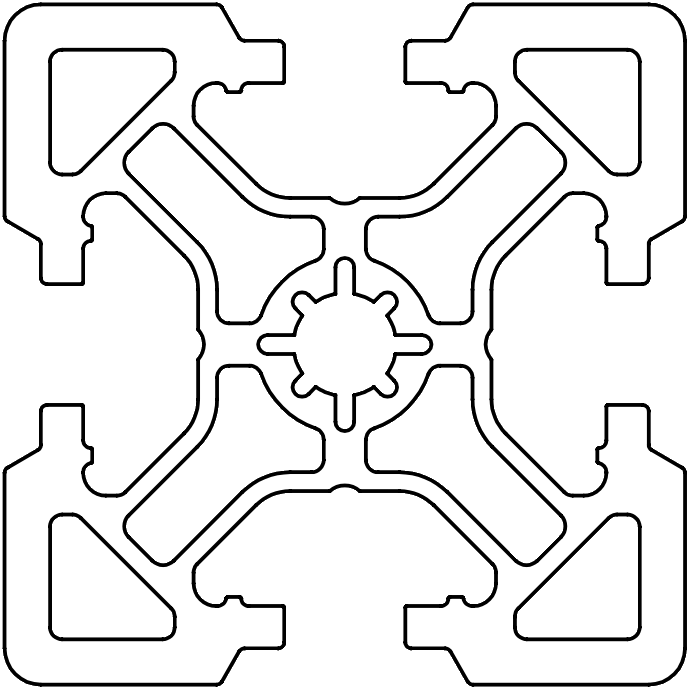

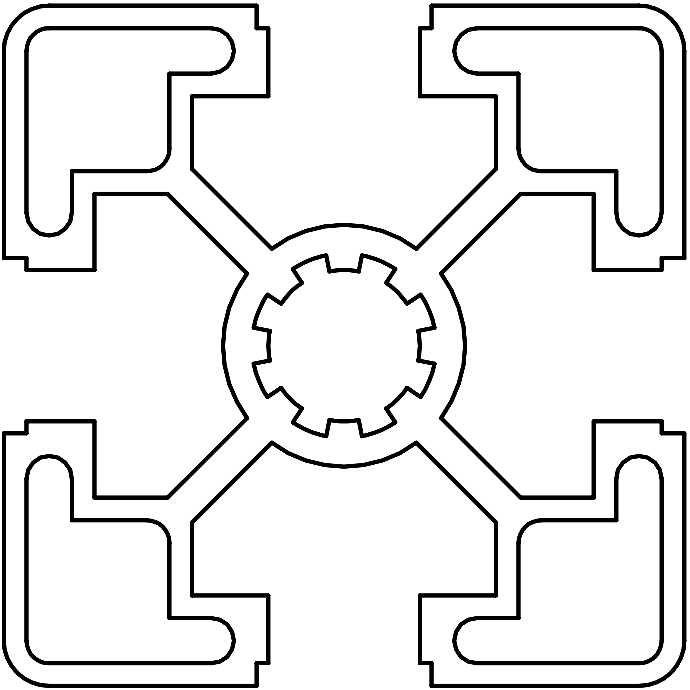

Technological reasons drive limited adoption of T-slot aluminum extrusions. Focus group research conducted with engineers working in automotive, aerospace, and engineering services industries highlighted nine common issues with existing T-slot aluminum extrusions, as seen below in Exhibit 1. Suboptimal performance in terms of structural rigidity and assembly tolerances has been the biggest impediment to the wider adoption of T-slot aluminum extrusions.

Poor length and angular tolerances on assemblies

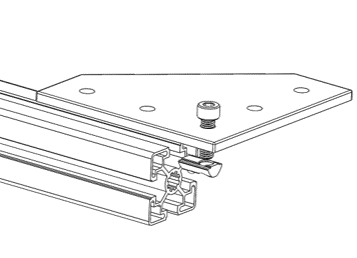

Since being introduced into the industry, aluminum extrusions have used assembly plates combined with T-slot bolts and nuts to create complete assemblies. Unfortunately, gains in assembly speed using this method have come at the expense of assembly tolerances, with the T-slot bolt acting as the locating device between the assembly plates and extrusions. The clearance fit on plate holes and T-slot width led to angular misalignment of up to ± 0.50mm per 25mm length, well below the accepted standard in several industries.

Poor strength-to-weight ratios

Because of the T-slot groove on each face, aluminum extrusions tend to have a lower rigidity than equivalent square tubing made of aluminum or steel. Such limitations have led to aluminum extrusions mostly being used for light-duty applications.

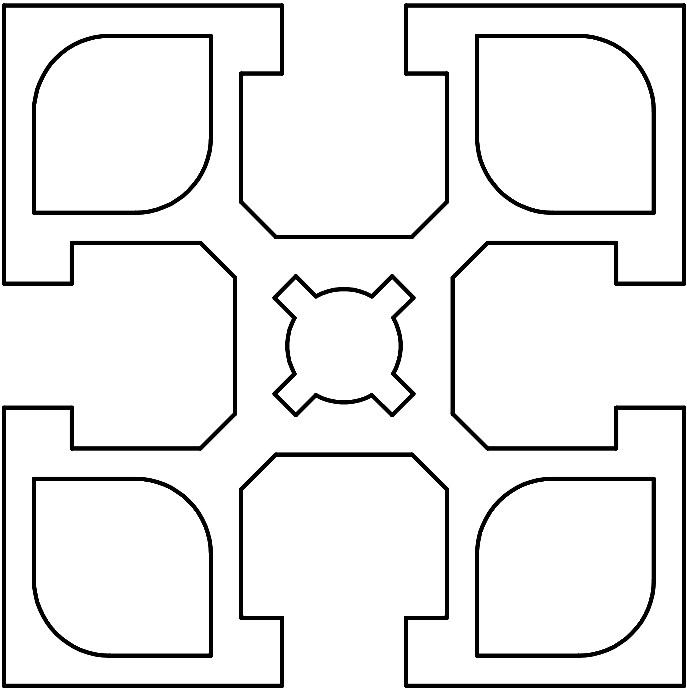

Exhibit 2. An example of a commercially available extrusion where the T-slot bolt acts as the locator between the assembly plate and extrusion

Achieving high-performance assemblies with T-slot aluminum extrusion

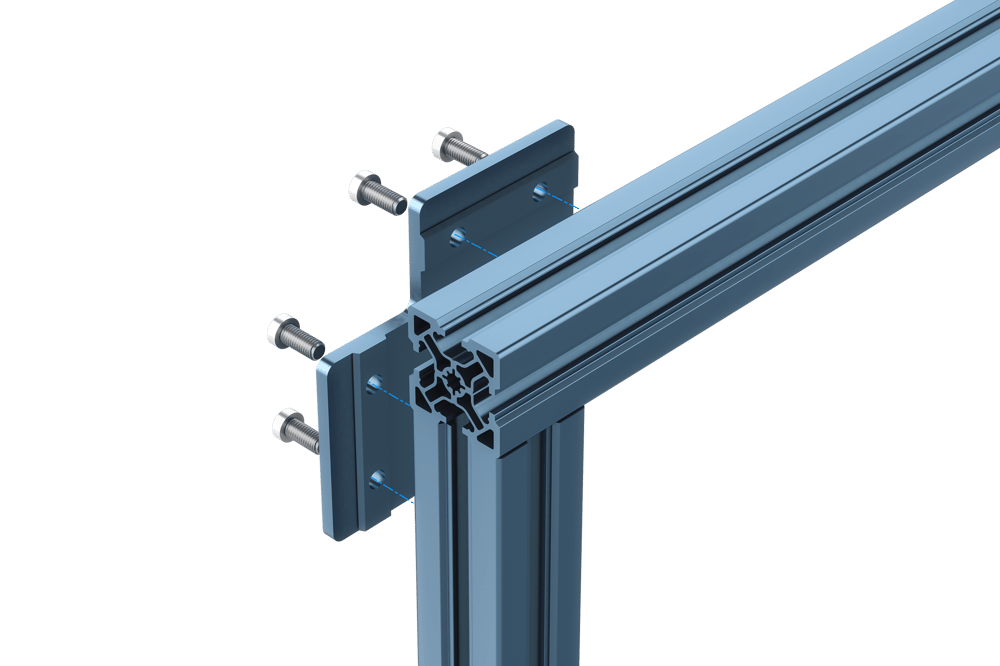

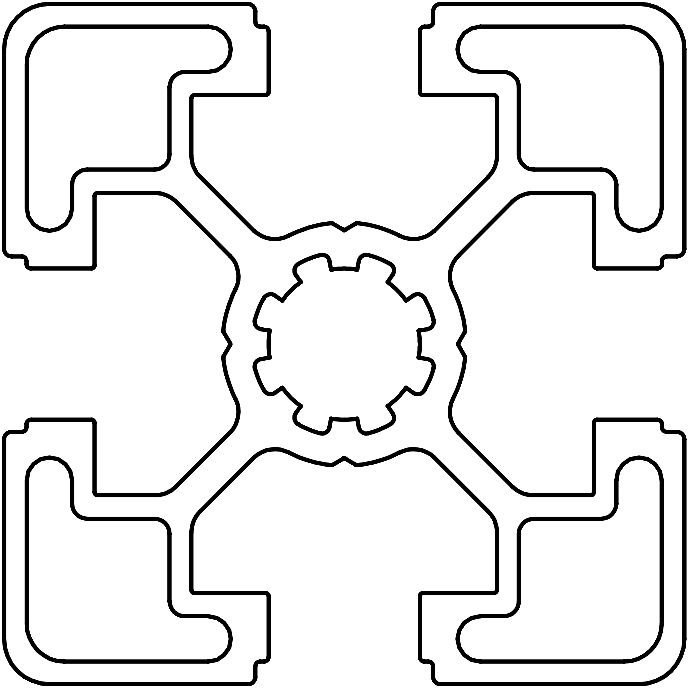

Our recent engineering task force has demonstrated that poor assembly tolerances and strength-to-weight ratios of T-slot extrusions could be resolved with an improved extrusion design.

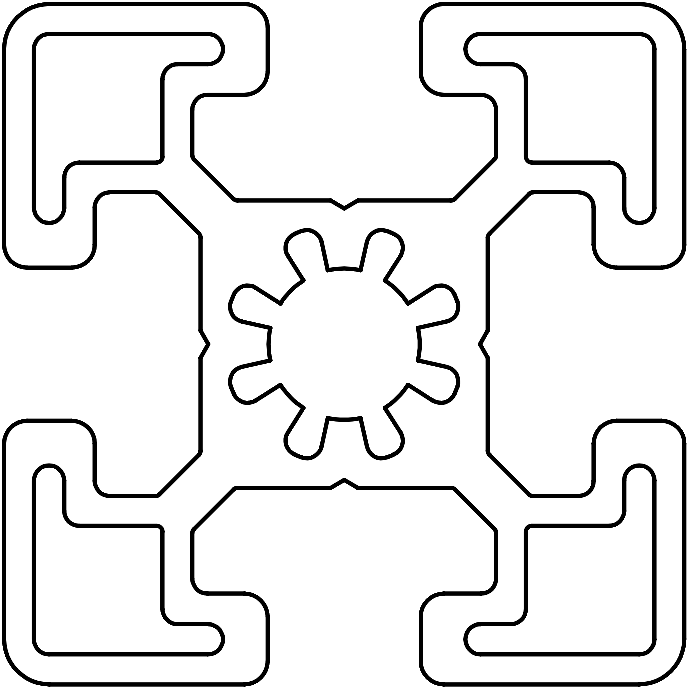

Achieving greater assembly tolerances

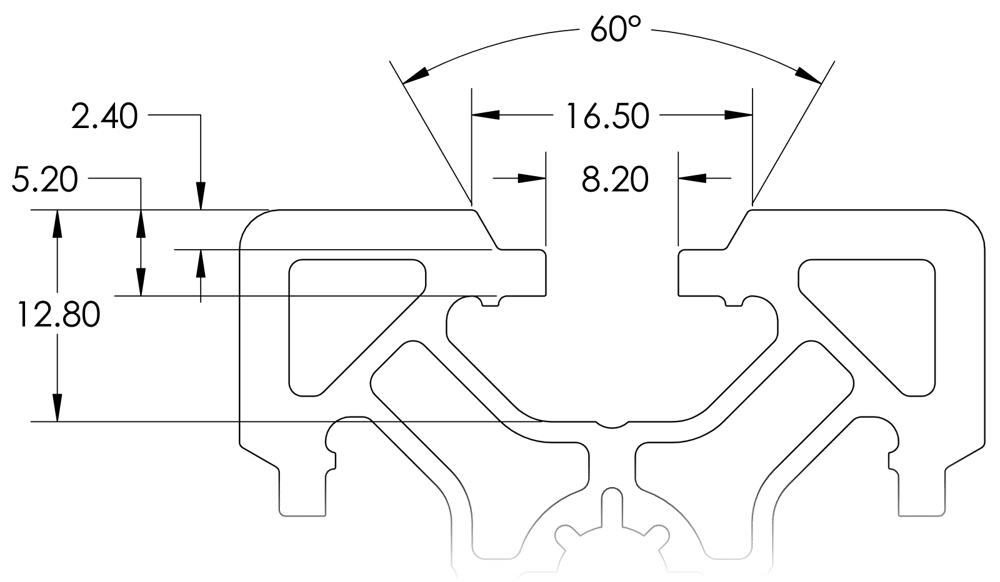

To ensure the precise positioning of one extrusion to the next, the interface system between T-slot extrusions and assembly plates had to be rethought.

|

|

| Exhibit 3. Self-positioning interface based on a “V-Shaped” T-slot groove | Exhibit 4. “V-Shaped” T-slot groove and corresponding assembly plates |

For example, an interface system based on a specially designed “V-shaped” T-slot groove acting as a part locator with the corresponding assembly plates (which include the male version of the “V-shaped” locator) could significantly reduce observed angular misalignment. Our engineers have shown that this self-positioning interface system allows for an angular tolerance of less than ±0.04mm per 25mm length at each angular node, a 12X improvement vs. commercially available T-slot extrusions systems.

Improving strength-to-weight ratios

Our engineering task force, through material distribution algorithms, demonstrated that the strength-to-weight ratio of T-slot aluminum extrusions could be improved by up to 15% vs. commercially available products. Those improvements are achieved with the same amount of material used (see the moment of inertia by the surface unit in Exhibit 5).

Translating such an optimized extrusion profile into the reality of industrial equipment implies lower structural deflection by up to 30% (see max deflection in Exhibit 5).

VENTION V2 |

Extrusion A |

Extrusion B |

Extrusion C |

Extrusion D |

|

|---|---|---|---|---|---|

| Profile Dimensions (mm) | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 |

| Material (aluminum) | 6005-T5 | 6560-T6 | 6105-T5 | 6063-T5 | 6063-T5 |

| Profile area (mm2) | 761 | 563 | 757 | 571 | 737 |

| Area moment of inertia (mm4) | 162,325 | 107,780 | 139,310 | 109,635 | 141,720 |

| Torsional constant (mm4) | 31,851 | 19,394 | 31,042 | 19,836 | 39,719 |

| Weight per meter (kg) | 2.06 | 1.63 | 2.05 | 1.55 | 2.03 |

| (Area moment of inertia) / (Surface Area)(mm2) | 213 | 191 | 184 | 192 | 192 |

| Max deflection (500mm cantilever) at 1500 N force (mm) | 5.58 | 8.28 | 6.50 | 8.25 | 6.30 |

| Stress (500mm cantilever) at 1500 N force (MPa) | 103.96 | 156.57 | 121.05 | 153.48 | 117.11 |

| Torsional displacement (1m length) at 50 Nm torque (degrees) | 3.46 | 5.68 | 3.55 | 5.55 | 2.77 |

Exhibit 5. Benchmarking of common extrusion profiles

Greater capacity with XL extrusions

Designed for the next generation of heavy-duty, 20-30 kg cobots, our newest extrusions, the XL extrusions (247.5 mm x 247.5 mm), rank best-in-class in terms of structural rigidity, straightness, and precision with their double wall design. These extrusions effectively reduce the complexity and the number of parts used in heavy-duty structures and are indispensable for large structures that require reinforcement and bracing, including an overhead 7th axis, a cartesian system, and more. Although small extrusions remain a possibility for building these structures, they require heavy reinforcing and bracing, which leads to a longer, more complex assembly process.

Designing joints with confidence

Vention has a large catalog of parts and extrusions. It is critical to select the correct components for each joint. Using our extrusion design guide, choose the correct profile, joint type, and joint orientation. By selecting the right parts for your design, a more optimized machine frame can be built.

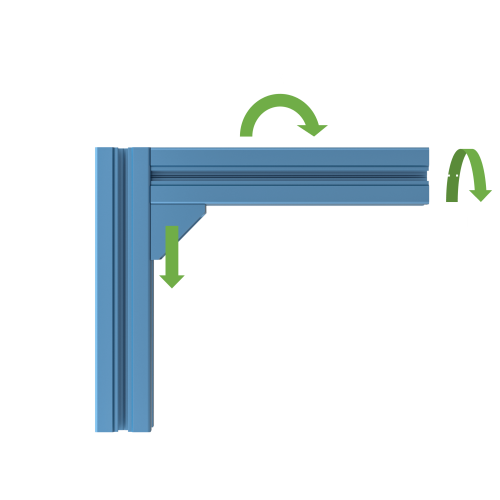

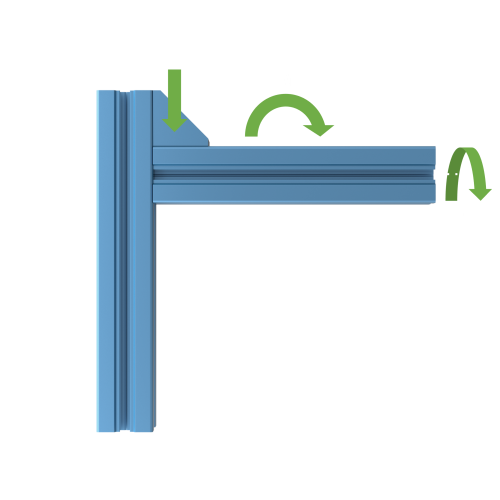

Consider exhibits 6 and 7. Switching the gusset from the top to the bottom improves the moment capacity (M) by 13% without changing the friction resistance (F) or torsional (T).

|

|

| Exhibit 6. Joint with gusset on top | Exhibit 7. Joint with gusset on bottom |

Calculating your machine’s strength

Before purchasing a heavy-duty application such as an overhead 7th axis or cartesian system, it is important to calculate your machine’s strength, rigidity, and friction joint capacity. To simplify these calculations, we have created a Deflection Calculator and a Joint Friction Calculator for you to use.

Deflection Calculator

Determining your machine’s strength and rigidity is easy with Vention’s t-slot aluminum extrusion deflection calculator. Simply select your extrusion profile, load distribution, and applied forces to get instant results for stress, deflection, and safety factors.

Friction Joint Calculator

Many joints made with extrusions rely on pure friction joints. Determine the load capacity of a joint fixed in place by pure friction by specifying the installation torque of the bolts and the number of fasteners in pure friction.

Try the Friction Joint Calculator

Conclusion

Shorter product lifecycles create pressure for custom industrial equipment to be rapidly designed, deployed, and repurposed at low cost. Fortunately, a modular hardware platform centered around T-slot aluminum extrusions could enable significant cost and lead-time gains over custom machined parts and welded assemblies. For such performance to materialize, those modular hardware platforms must solve for reduced assembly tolerances and higher structural rigidity.