It is well-known that t-slot aluminum extrusions enable fast design and manufacturing of structural frames. That being said, the overall structural integrity of such assemblies can be significantly improved through various design considerations and analyses. Below are three top design tips to create industrial-grade, rigid, and reliable t-slot aluminum extrusion structures.

1. Select the right extrusion profile

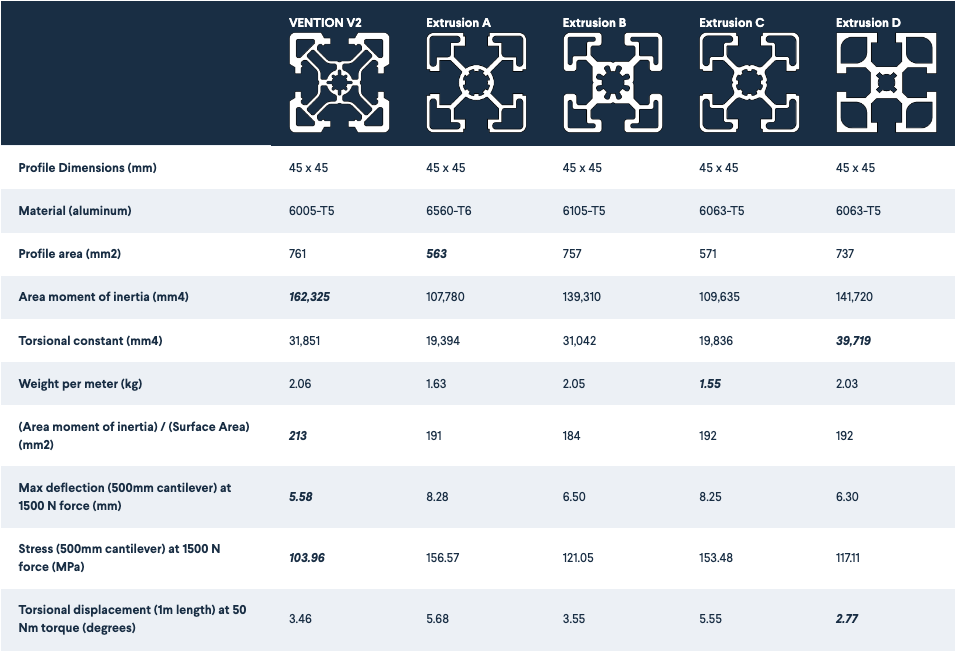

All extrusion profiles are not created equal. The rigidity of profiles with similar outer dimensions (e.g., 45 mm x 45mm) can significantly vary based on their moment of inertia with some profile geometries leading to a 40% stiffer beam. Another key aspect to consider is the cross-section’s area, which has a direct impact on the overall weight of the assembly. Given that the best profiles are highly rigid, yet lightweight, the best performance indicator is the moment of inertia to surface area ratio. The table below compares Vention against four other extrusion brands.

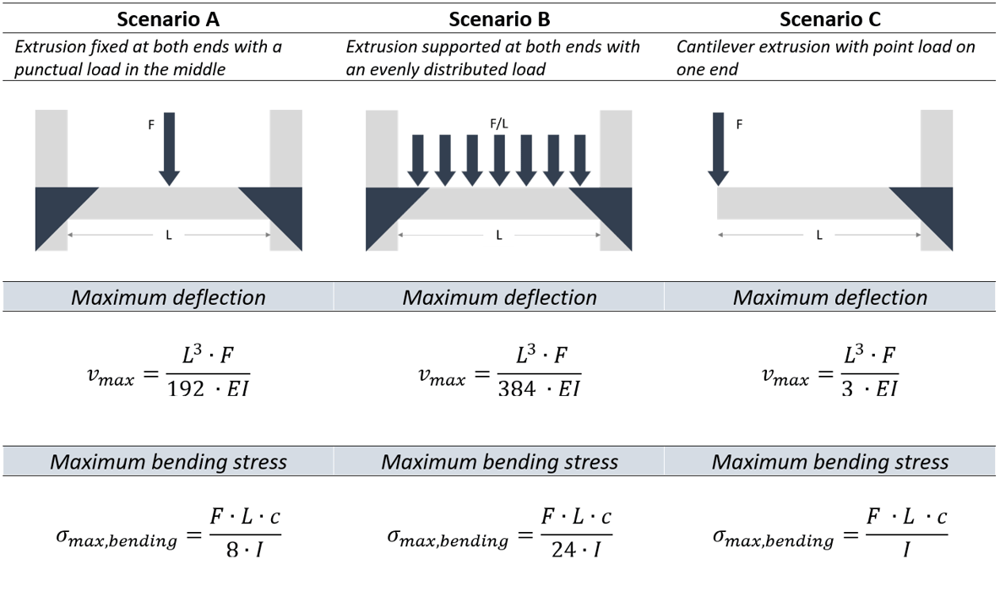

In order to determine if a profile meets your design requirements, start by estimating the applied load on the structure, and then on each individual extrusion, through free body diagrams and basic static calculations. Once determined, use the formulas below to calculate the maximum deflection and bending stress for each of your critical extrusions, based on your application.

Where:

Comparing the maximum bending stress with the material’s respective yield strength (141 N/mm2 for Vention’s 6063-T5 aluminum) provides a rough order of magnitude for your extrusion’s capacity to withstand the required load. However, it should not be used alone as a precise value, since it does not take into consideration other factors, such as the extrusion’s own weight and the shear stress.

2. Carefully select your extrusion joint configuration

Selecting the right extrusion profile is only part of the work required to come up with effective structures. The assembly joint configuration can also substantially change the rigidity and structural integrity of a design.

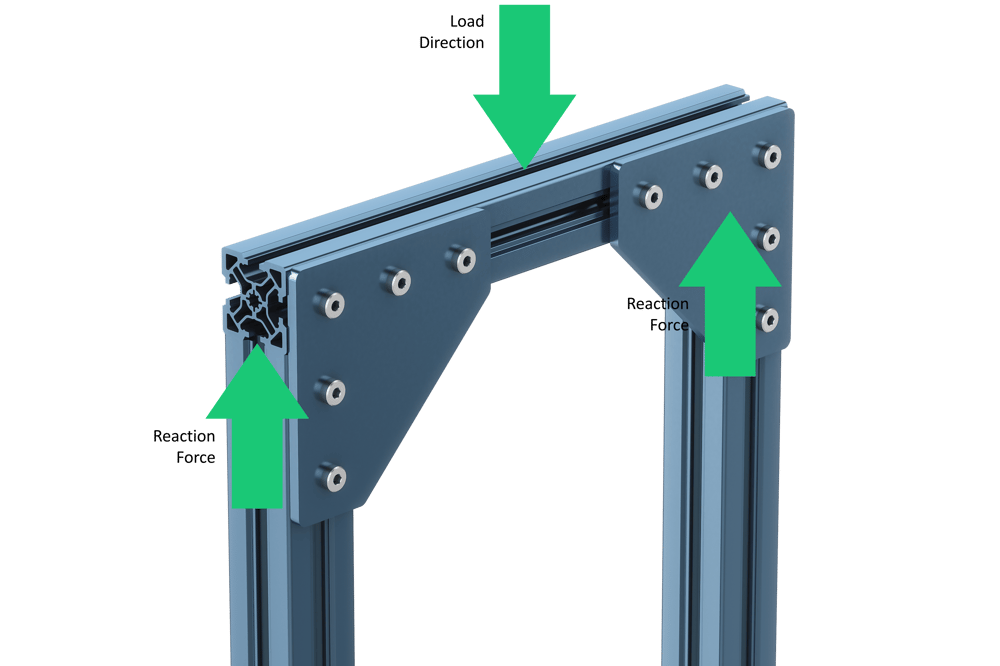

One thing to avoid is assembly joints relying solely on friction to support the load. A better approach is to position one extrusion on top of another, as seen in the images below. Assembly plates then hold all of the pieces together but only withstand a minimal amount of force.

Friction joint (not recommended): Lower strength; force transmitted through friction between plate and extrusion.

Reaction force-based joint (recommended): High strength; force transmitted directly to the frame via contact with vertical extrusions.

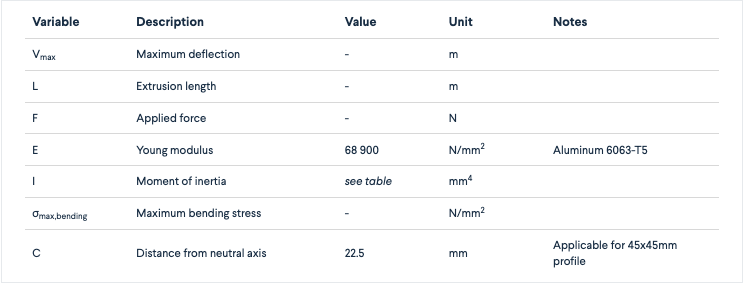

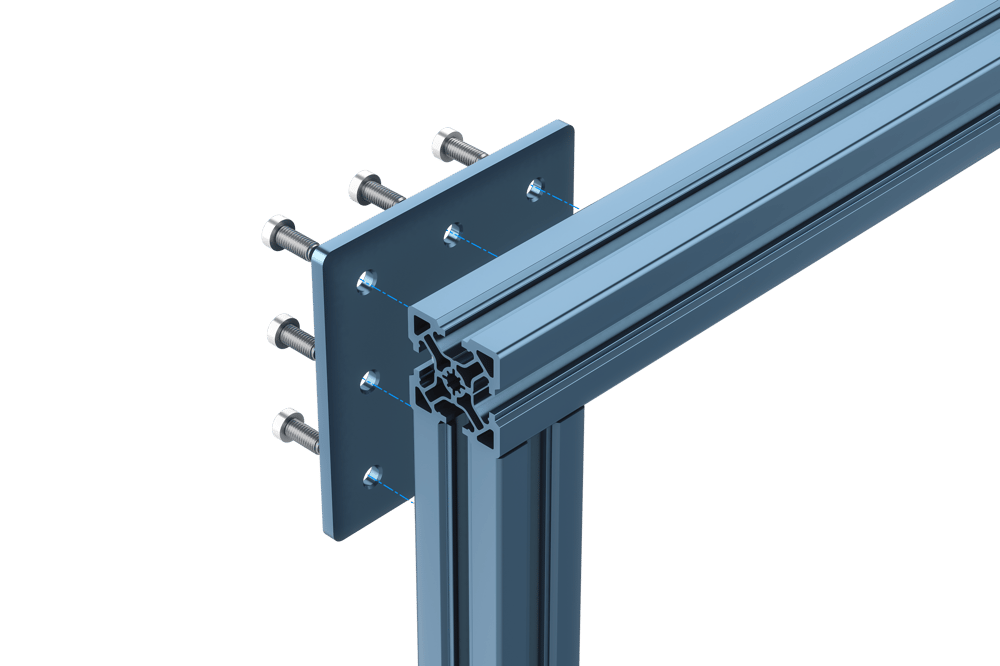

However, assembly joints relying only on friction cannot always be avoided. For such cases, designers need to understand how much friction can be generated by a single fastener and multiply by the number of screws that are solicited.

In the example below, assuming each fastener can generate 2,100N of friction when tightened at 13Nm, the horizontal beam could support a maximum load of 12,600N (i.e., 2,100N per fastener x 6 fasteners). Using this simple approach, you can easily properly right-size the required assembly plates for each joint, choosing between one-fastener plate or up to eight-fastener plates.

Interestingly, this step of the design process is most helpful when it’s time to optimize the cost of a design, as people tend to over-design and misunderstand how strong their joints can be. Out of the designs we see every week here at Vention, our applications engineers are typically able to reduce costs by up to 15% by changing existing assembly plates for more appropriate parts.

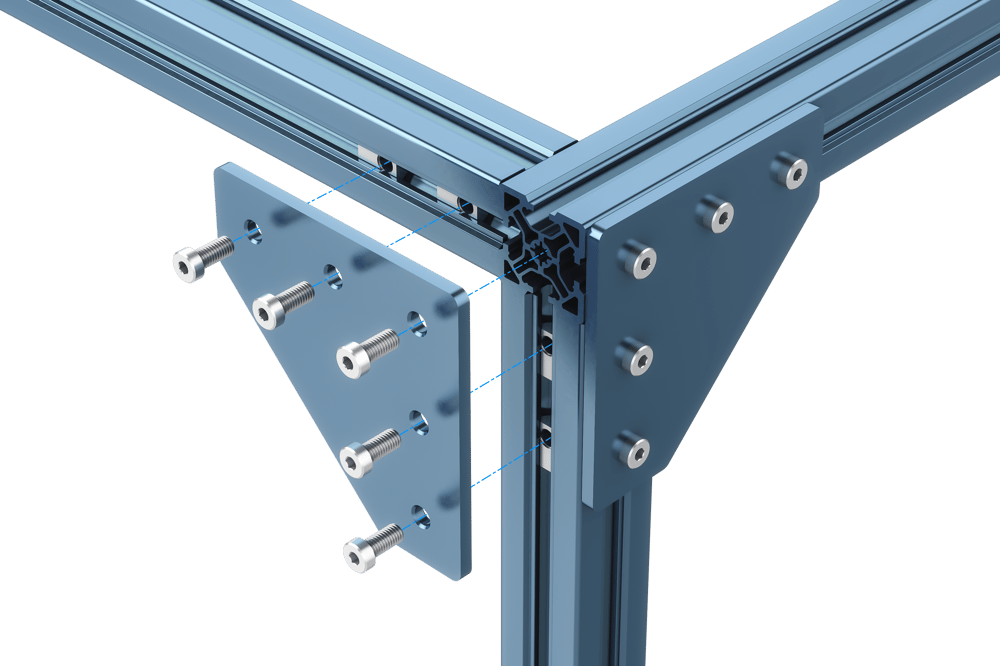

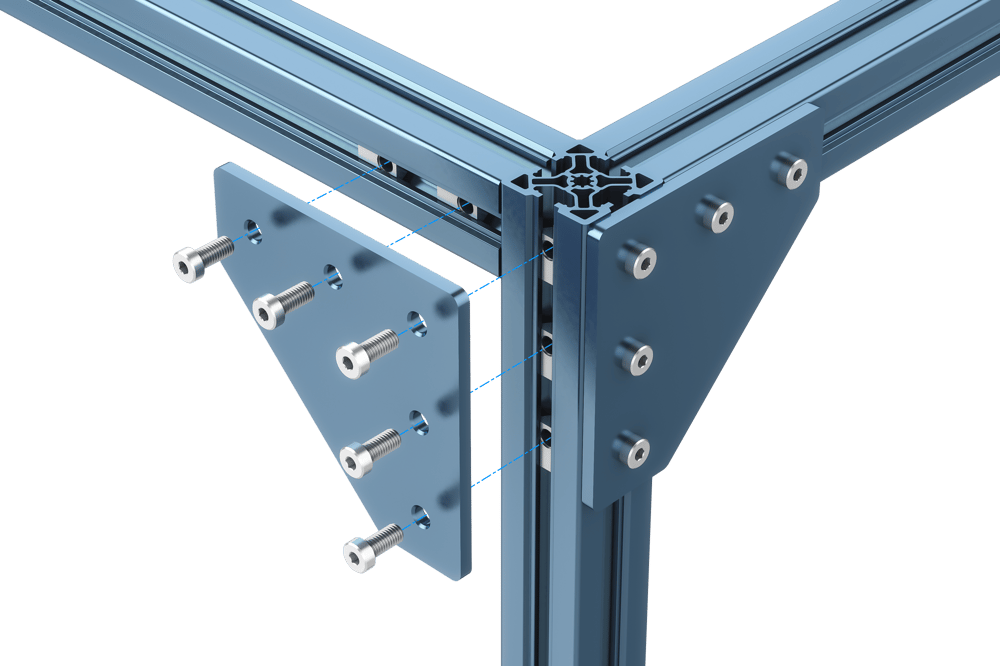

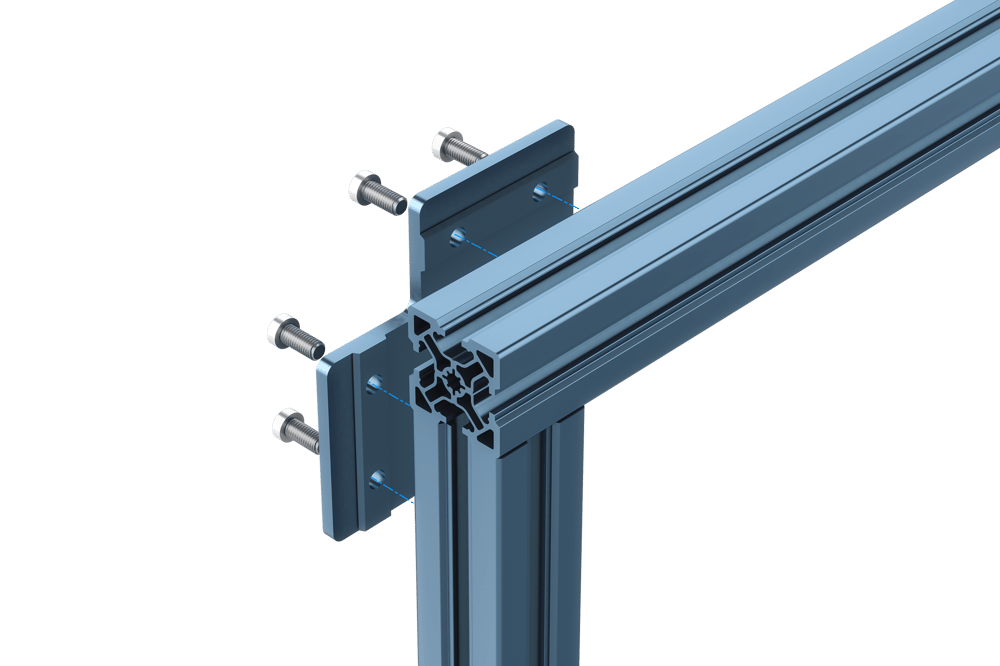

Another tip I particularly like when creating “three-way joints” is to transform what could have been a friction-only joint into a rugged connection by threading one of the fasteners directly into the extrusion’s end. By uniting three different extrusions in such a configuration (i.e., one vertical and two horizontal), none of the plates depend on friction alone.

Strong three-way joint: one bolt threads directly into the end of the extrusion.

Weak friction-only joint, bolt does not thread into the extrusion end. (These are sometimes unavoidable.)

3. Use high-strength extrusion systems for demanding applications

Combining effective assembly joints with the appropriate extrusion profile can definitely improve the structural integrity of your assemblies. For heavy-duty or precise applications, Vention strategically added a patent-pending V-shaped boss underneath all of its high-precision assembly plates (i.e. ST-HP-XXX-XXXX), creating a more solid interface between assembly plates and t-slot extrusions. The fact that those bosses lock into the extrusion grooves provides two primary benefits:

- It eliminates angular misalignment, as the plates are no longer located by their screw’s loose clearance holes.

- It increases slippage resistance by converting friction joints to structurally bonded joints.

Many plates come in GP (general purpose) and HP (high precision) variants. Your choice depends on whether you want to optimize for lower price (GP) or higher strength and precision (HP).

GP connection example

HP connection example

In conclusion

Aluminum t-slot extrusion structures have become a real alternative to welded steel structures for many applications. To create effective aluminum frames, a few design guidelines must be taken into consideration. For more information on this topic, read our design guide: Designing with T-slot Aluminum Extrusions. If you need design assistance with your project or simply want to confirm some design parameters, reach out to our team of application engineers or email us at support@vention.cc.