Datasheet

Updated: Tuesday, August 10th 2021

MachineMotion Pendant

Overview

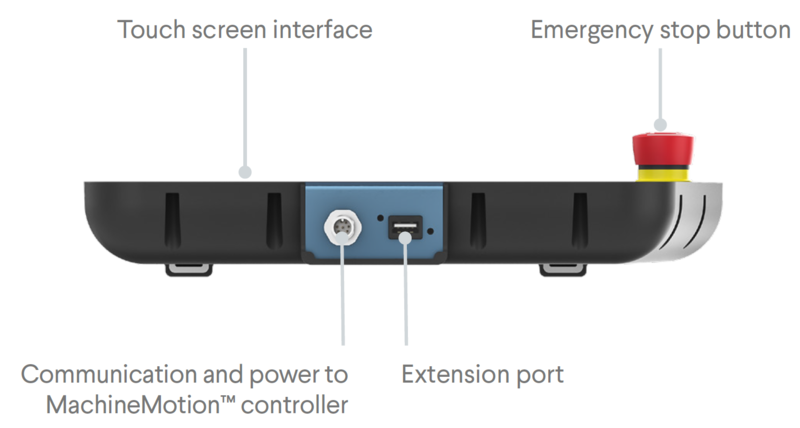

MachineMotion™ Pendant provides a plug and play touch screen interface for automated equipment powered by the Vention MachineMotion™ controller. When connected to the MachineMotion™ controller, the pendant enables machine operators and administrators to run and modify their MachineApps through an intuitive, code-free user interface.

Features

- Plug and Play compatibility with MachineMotion™ controller

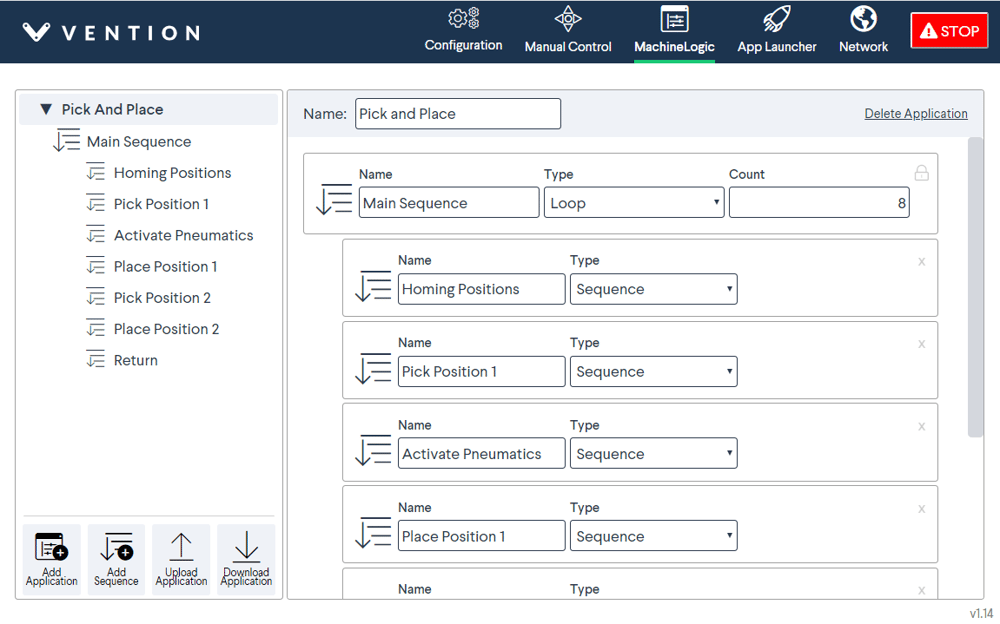

- Pre-loaded MachineLogic™, for code-free automation sequence editing

- Application launcher for machine operators

- User rights management

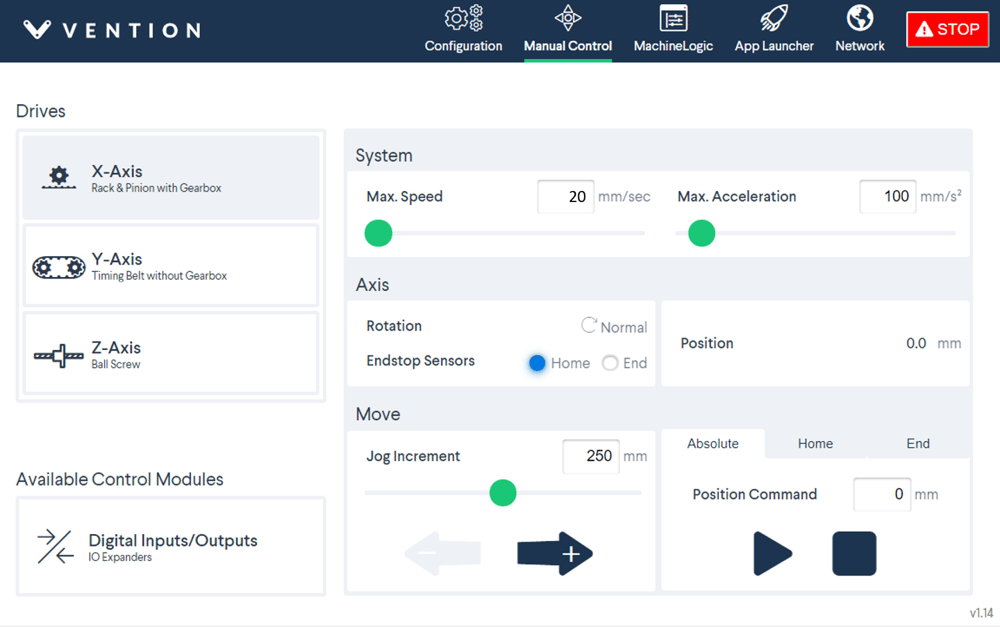

- Manual machine operation mode

- Connect to Vention’s cloud-based MachineBuilder 3D

Applications

- Automated equipment

- Cartesian robot

- Functional and reliability test benches

- Conveyor system

- Inspection cells

Software Included

MachineMotion™ comes with pre-loaded control and machine operations software – all of which is accessible through the MachineMotion™ pendant or via computer with a USB or Ethernet connection.

Applications Launcher

Manual Mode

MachineLogicTM

Technical Specifications

Electrical Specifications

| Processing | |

| Processor | Quad-core Cortex-A53 @ 1.4 GHz |

| Memory | 32 GB flash storage, 1 GB RAM |

| Emergency | |

| Wired emergency stop button |

Input/Output Specifications

| Power | |

| Type | Single cable to MachineMotion™ dedicated port |

| Network | |

| Wireless LAN | |

| Band | 2.4 GHz and 5 GHz |

| Physical Layer | IEEE 802.11.b/g/n/ac |

| Screen | |

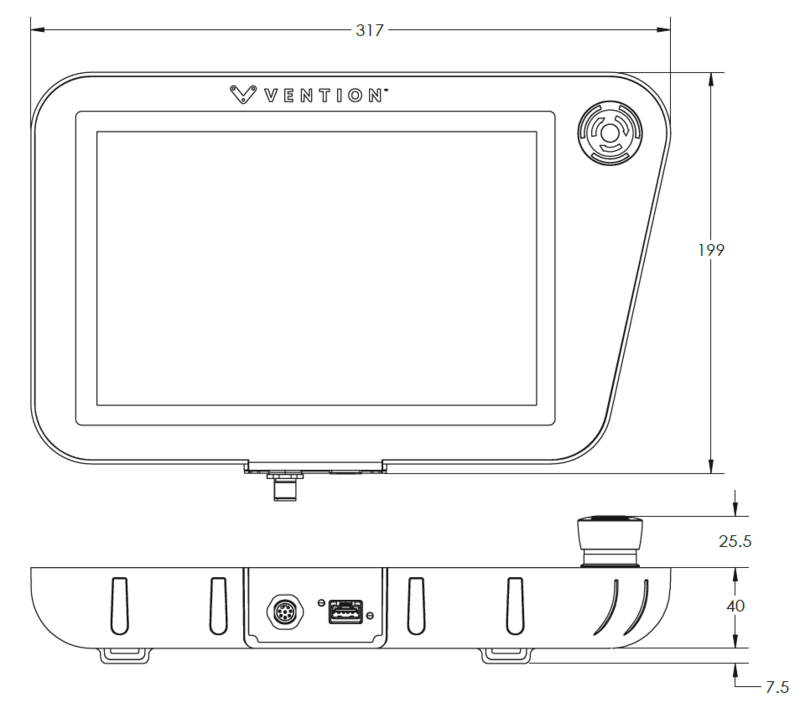

| Resolution | 1280 x 800 |

| Screen Size | 10.1” |

| Type | LCD capacitive touch |

| Extension | |

| Connector Type | 1x USB Type-A |

| Physical Layer | USB 2.0 |

Hardware Compatibility

| MachineMotion 1 controller | CE-TP-003-0001 |

| MachineMotion 2 controller | CE-TP-004-0001 |

Included Software

| Installation | Manual Machine Control |

| Access | User Management |

| Operator | ApplicationLauncher |

| Programming | MachineLogic™ |

Mechanical Specifications

| Shock-resistant enclosure |

| Rear mounting tabs |

| Hand strap |

Physical Unit

Functional Pinout

Unit Dimensions