How to guide

Updated: Tuesday, November 28th 2023

Deploy your Application and Configuration to Controller

Contents

Deploy your Application and Configuration to Controller

Introduction

This guide covers the setup and use of Vention’s MachineLogic. MachineLogic is a visual programming and simulation tool dedicated to the creation of MachineMotion programs. It provides a simplified programming experience and is compatible with Vention’s plug-and-play automation components. After reading this guide, you will be ready to deploy custom motion and control applications using Vention’s MachineMotion controller.

Setting up your MachineMotion controller

We recommend reading the MachineMotion: User Manual to understand the different methods to interface with the controller (computer, or MachineMotion pendant). MachineLogic can be accessed directly from a web browser—no installation necessary. To get a MachineLogic program onto your controller:

- Connect your MachineMotion controller to a 90–120 V alternating current (AC) power source.

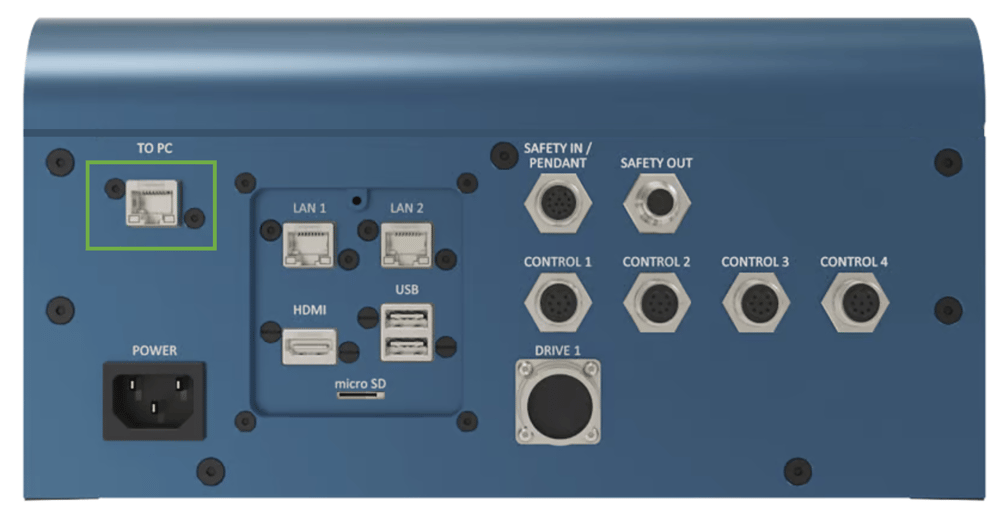

- Connect the Ethernet cable in the “TO PC” port to the Ethernet port on your computer

- Flip the main-power/rocker switch to TURN-ON the MachineMotion controller. Note that upon turning on the controller, wait for the status LED to turn green (~ 90 seconds).

- Open a web browser (we recommend Google Chrome for guaranteed compatibility) and enter 192.168.7.2 in the address bar.

- You will see the following UI below. Ensure you release the red e-stop button on the controller before proceeding. Once released, click “RELEASE” to release the software stop. Click “RESET” when you are ready to operate the machine. The status LED should display green once this step is achieved.

Steps to deploy a MachineLogic program to your MachineMotion controller

- Log on to your vention.io user and select the design you have previously programed in MachineLogic

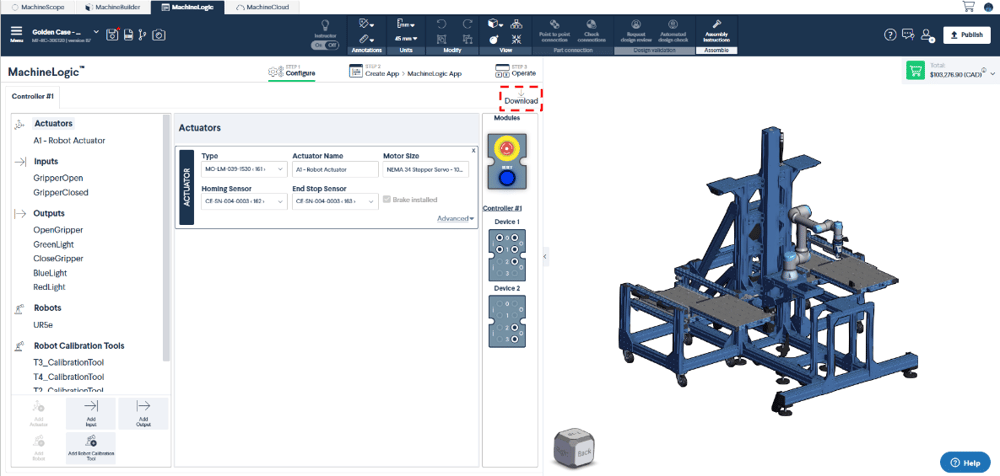

- Download your configuration file from your MachineLogic application configuration tab

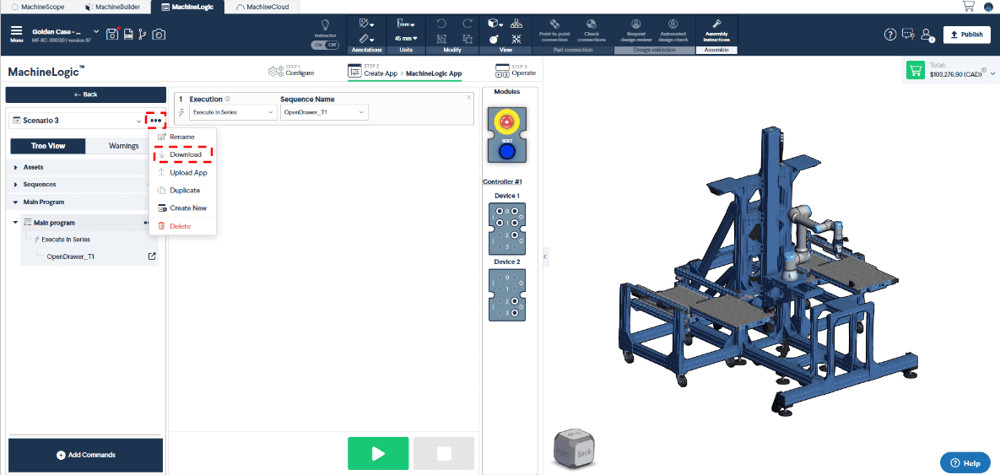

- Download the application you want to deploy on your MachineMotion

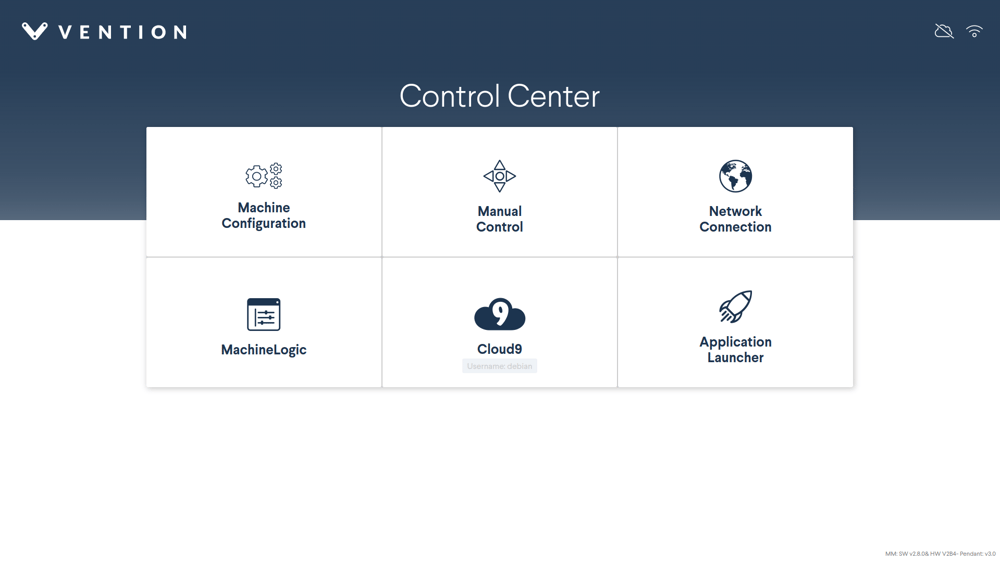

- Go back to the 192.168.7.2 web browser tab and you should see the following view.

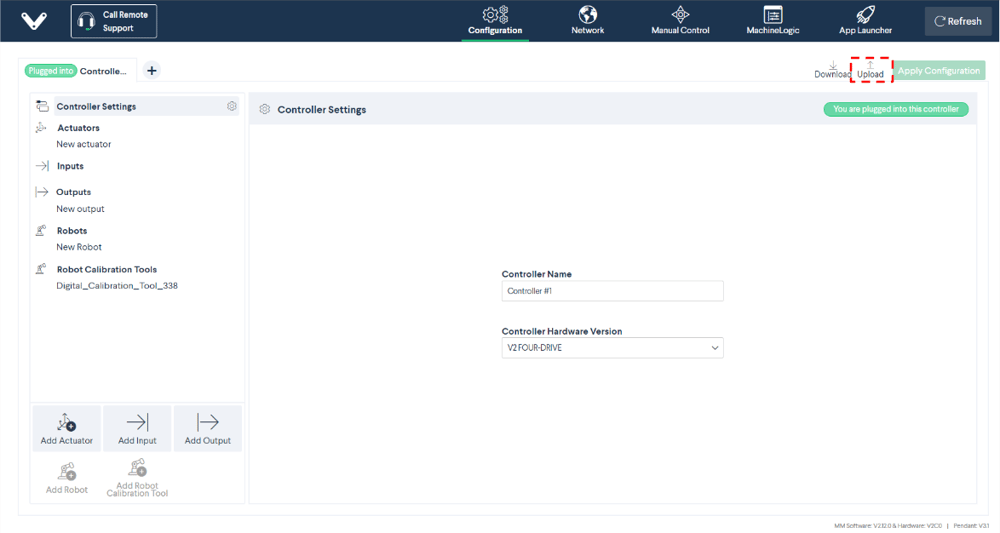

- Click the MachineConfiguration tile and press the “Upload Configuration” button. Select the previously downloaded configuration file.

- Confirm that all your data represent properly your machine. Once you’re done, press the “Apply Configuration” button.

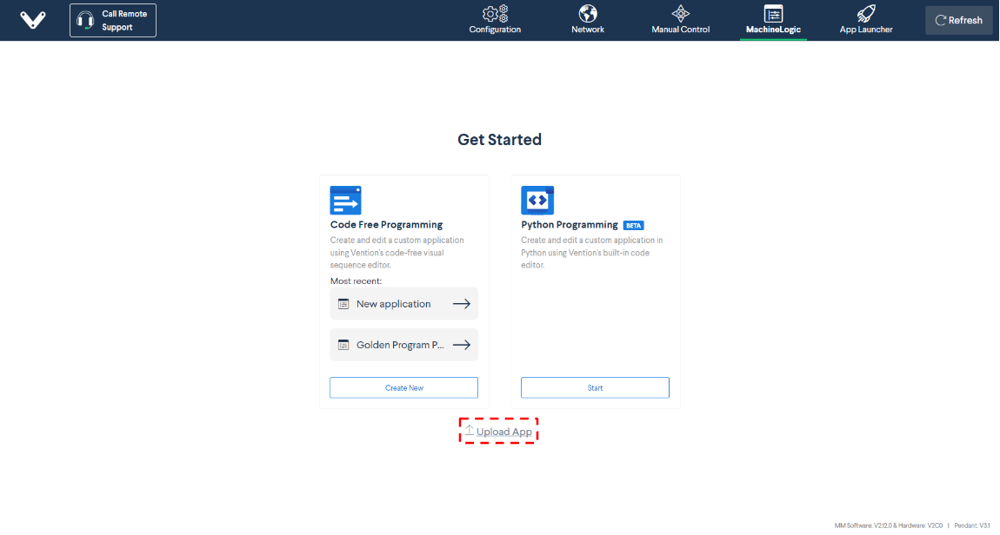

- Click the MachineLogic button from the navigation bar.

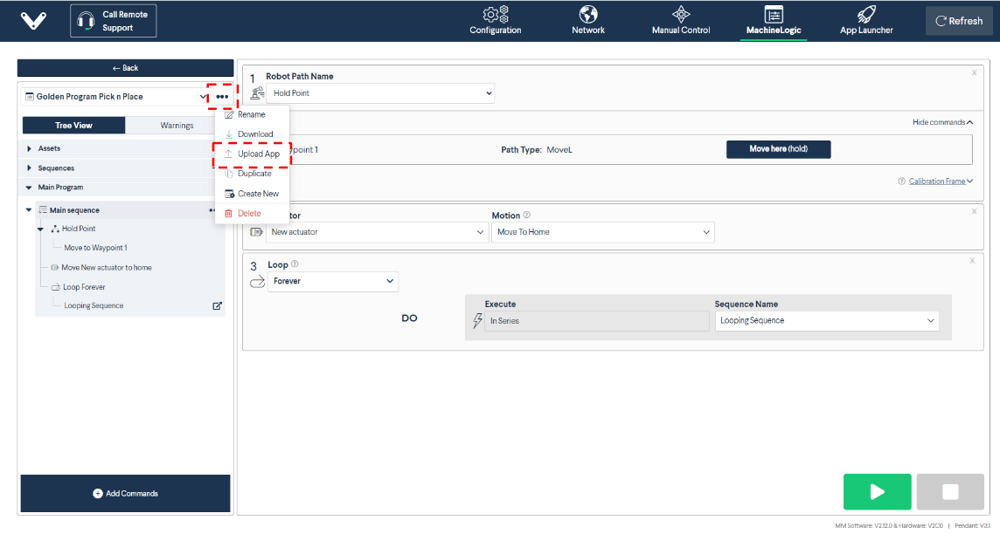

- Press the “Upload App” button and select the application you have previously downloaded.

- You can also upload your application from the following view. Once you’re done, you can then press the play button to run your application.