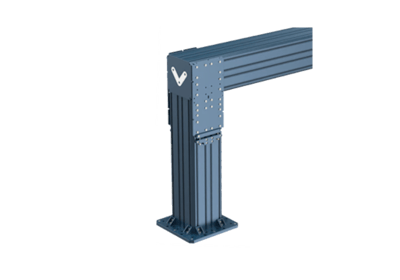

Structural & Framing

How to use Vention structural hardware and accessories to create machine frames, industrial furniture and much more.

Guides

Datasheets

Structural & Framing FAQs

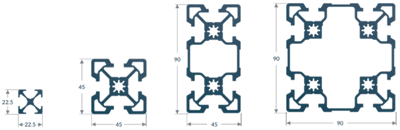

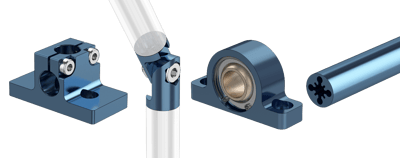

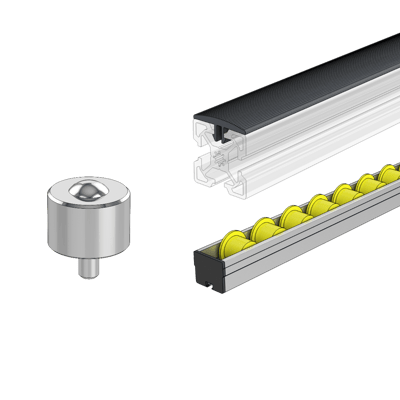

Vention extrusions are made of 6005-T5 aluminum, and machined parts are made of 6061-T6 aluminum. The part description cards (found in the parts library) detail the materials used for every Vention part.

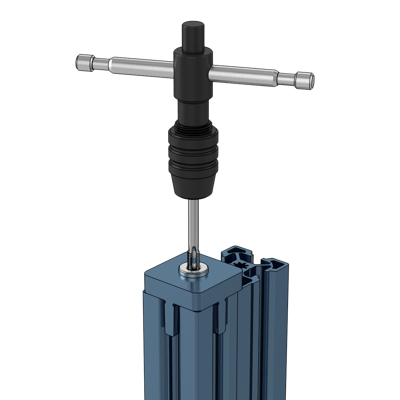

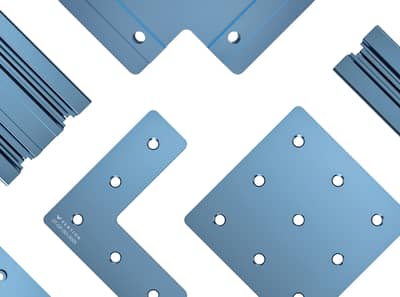

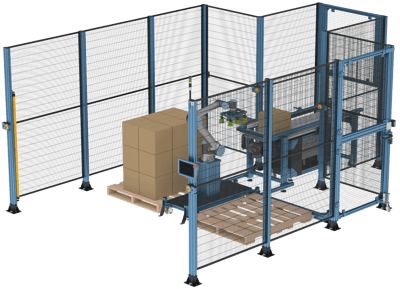

For structural parts, Vention’s pricing is comparable to other large industrial distributors. Note that Vention extrusions do not require any machining such as access bores or bore holes. In addition, Vention doesn't charge any cutting fees for any of its standard length. Lastly, note that all of Vention's gussets, joints and assembly plates, come with the associated fasteners. Similarly, for industrial automation parts, Vention’s pricing is generally much lower than that of traditional players because of our innovative approach.

We provide a fully integrated, single-box motion controller—which means our customers don’t have to create a custom control enclosure from individual components like a drive, power supply, PLC, and so on. The cost of a Vention control system is generally 50% lower than a traditional custom-made control enclosure that integrates all the required automation hardware.

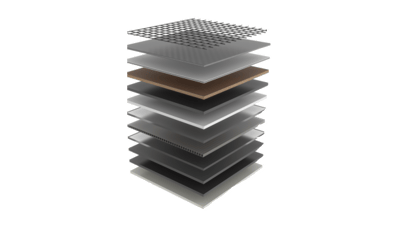

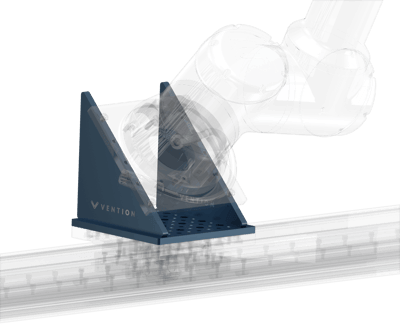

Vention uses a standard 6 micron-deep blue anodization. This color, which we call “Vention blue,” has low reflectivity. On machined parts, we perform a light shot peening before anodizing, which results in a dull orange-peel textured finish.