Digital manufacturing is reducing tooling cost by 40%

Despite the latest innovations in engineering software, the design and manufacturing of tooling remains highly manual with a series of segregated web and desktop environments that designers must navigate to complete their project. It is easy to imagine all the time spent on industrial distributors and part manufacturers’ websites figuring out part compatibility before the first part is ever assembled in SolidWorks or Inventor.

Working with our customers, Vention led 5 different “tooling project deconstruction” exercises to quantify work content, schedule, and costs associated with each design step from “ideation to purchase of the complete equipment”. Those custom projects were then reconstructed using our Manufacturing Automation Platform (MAP). Acting as a “single digital thread,” MAP unites the selection of modular tooling parts, cloud-based 3D design, and online purchase of the designed tooling under one platform.

Cost Areas and Cost Opportunities in Tooling

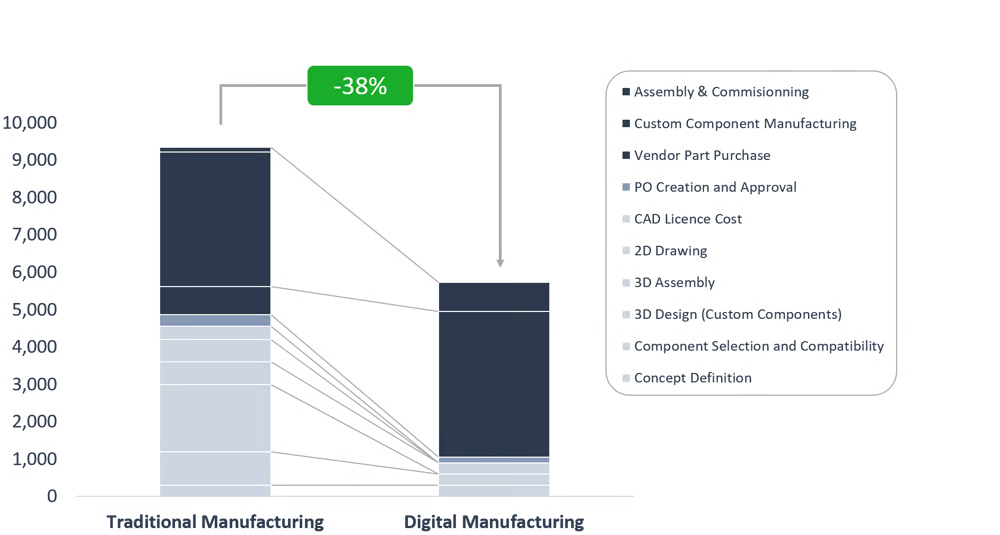

Our research demonstrated that on average, 50% of the total cost for a tooling project is related to engineering and procurement hours, while the remaining 50% is related to material, manufacturing, and assembly costs for vendors and custom parts. Interestingly, unifying all the steps from part selection, to design, to purchase under MAP not only accelerates lead-time by up to 10x but also reduces cost by approximately 40%.

Compressing the Engineering and Procurement Workflow

Out of the 40% savings identified, 28% came from a significantly compressed “engineering and procurement” workflow. In MAP, tooling engineers create assemblies out of modular and off-the-shelf parts (see our Parts Library). Those modular parts can be selected and bought directly in MachineBuilder, our cloud-CAD design environment. Thus, no more custom part designs are required with 2D drawings becoming unnecessary.

The remaining 12% of identified savings came from significantly accelerated vendor part selection (i.e., happening directly inside MAP vs. on various distinct websites), 3D assembly (supported by smart CAD connectors specific to modular parts), and procurement process (involving “straight-through” online purchase).

Total Average Cost for a Tooling Project

Including engineering, procurement, manufacturing, and assembly.

Implications for Tooling Engineers

As the product lifecycle keeps getting shorter, engineers are under pressure to create tooling that can be rapidly designed and deployed at low cost. Fortunately, recent developments in digital manufacturing have paved the way for the integration between 3D CAD software and modular industrial hardware, enabling significant savings and a much shorter project timeline.